1325-2 CNC Router Machine Price

RC1325-2 CNC Router Machine Price

Features:

1. Labor cost: get rid of the dependence on skilled workers, and can efficiently complete the blanking work.

2. Plate utilization: Because the milling cutter is used for blanking, the direction can be adjusted at will, and even nesting can be performed. The utilization rate of the plate can reach 93%.

3. Software support: proprietary software support, NC file output, blanking error free, zero error, no unexpected error cost, no waste.

4. Special shape support: arc, corner cutting, trapezoid, tie box are formed at one time, which eliminates the need for later engraving, high utilization rate of plates, and saves the need for later manual secondary processing.

5. Manual labeling: the label is the display information of the material in the mixed opening. The complete label information can quickly realize the plate sorting and improve the efficiency.

6. Processing effect: because of the characteristics of the milling cutter, the processing surface will be very flat, there will be no black line burst, the edge sealing effect will be improved, there is no need to make up for the cutting defects in the later stage, which saves the workload of the packaging and cleaning workers, and improves the packaging efficiency.

7. The working intensity of the automatic loading and unloading cutting machine in the fourth process: because the automatic loading and unloading can be added, the workers work very easily, and the physical requirements of the workers are low. Even female workers can easily be competent for the cutting work.

8. No potential safety hazard: the workers have no contact with the cutting and milling cutter, and there is no danger, which avoids the occurrence of industrial accidents, and the boss is relieved.

9. Working hours: You can work 24 hours without interruption, even at night, because the machine does not require much light, and the workers only operate on the computer, greatly improving the production capacity of the factory, and realizing the ability of a CNC cutting machine to top four reciprocating saws.

10. Function extension: You can carve molded doors. As long as you buy another laminating machine, you can start the molded door project. The number of factory operating projects increases, the number of profit points increases, and the workers can work at full capacity.

Main parts:

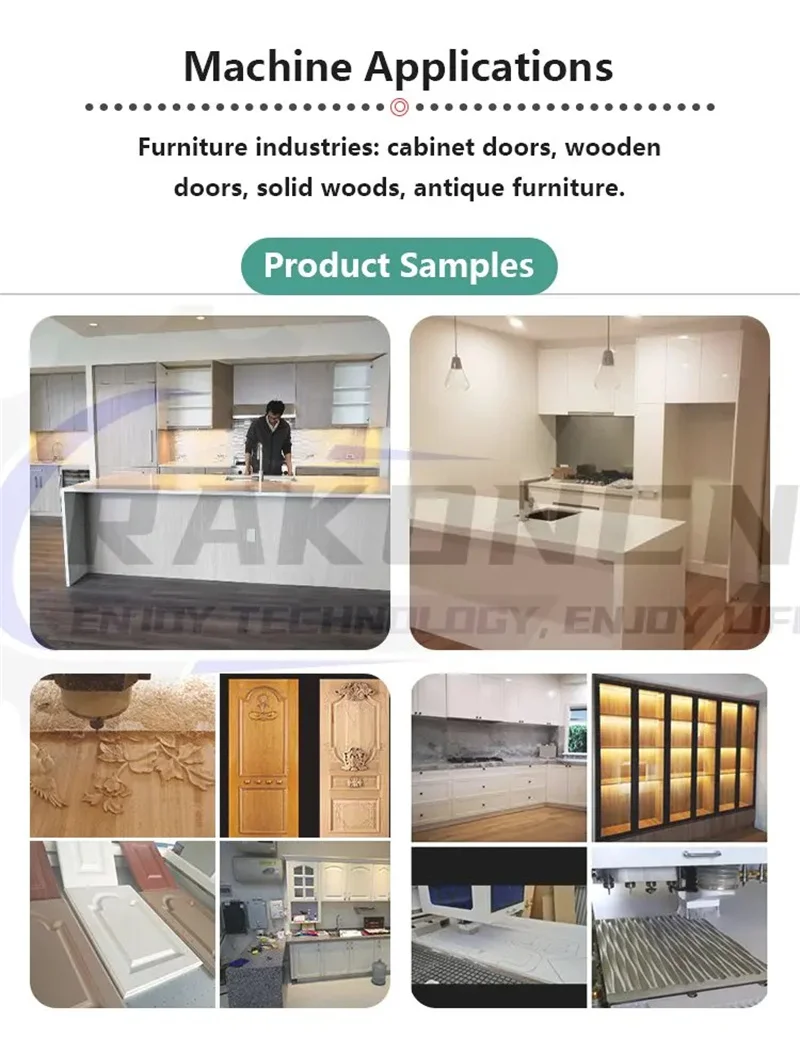

Applications:

1. Wood Furniture Industry: Wave Plate, fine pattern, antique furniture, wooden door, screen, craft sash, composite gates,cup board doors, interior doors, sofa legs, headboards ,game cabinets, computer tables, sewing machines table, instruments etc.

2.Advertising Industry: advertising identification, sigh making, Acrylic engraving and cutting, crystal word making,blaster molding,and other advertising materials derivatives making

3. Crafts: engraving characters of any language and patterns on gifts and souvenirs, primitive processing and shaping of artistic crafts, and stiletto

4. Moulding: engraving delicate letter and flower pattern, primitive and fine processing of the small mould.

5.Architectural models: engraving fine window, fencing and wall patterns, etc.

Application materials:

1.Wood: Plywood, Soft Wood, Hard Wood, MDF, Chipboard, etc.

2.Plastic: Acrylic, ABS, HDPE, PVC, UHMW, HDPE, etc.

3.Metal: Aluminium, Brass, Copper, etc,it needs extra cooling system .

4. Composite: Aluminium Composite, Copper Composite, Titanium, Composite, Zinc Composite, etc.

5. Plastics & Composites (ACP, ACM and solid surface material etc)

Specifications:

Model | RC1325-2 |

Working Area | 1300×2500×200mm |

Spindle Motor | 3.2kw water cooling spindle / air cooling |

Working Mode | Stepper motor(servo is optional) |

Control System | DSP controller; Shanlong / LNC optional |

Drive Mechanism | Rack and pinion on x,y axis ,z axis ball screw transmission |

Table Surface | T-slot table (vacuum table optional) |

Frame | Seamless welded steel structure |

Motion Positioning Accuracy | ± 0.03/300mm |

Repositioning Accuracy | ± 0.05mm |

Max Motion Speed | 30,000mm/min |

Max Engraving Speed | 25,000mm/min |

Rotating Speed of Spindle | 2,4000rpm |

Z-axis setting | Auto Z origin tool sensor |

Dictate Format | G code, *.u00, *.mmg, *.plt |

Operating Voltage | 220V/ 380v |

Software | Type3, ArtCAM software |

Packing Size | 3100*2250*1850mm |

Lubrication System | Oil lubrication system |

Gross Weight | 1000kg |