Features:

1. Z-axis feed height 150mm (height can be increased)

2. Cast iron bed, strong enough.

3. T slot or Vacuum workbench, zone control, convenient for fixing materials.

4. X-Y-Z axis adopts TBI ball screw drive, high precision

5. Stepper motor and driver (servo motor and driver optional), fast speed and good stability.

6. 1.5kw water-cooled spindle and Fuling inverter, fast spindle cooling and low noise.

7. Nc studio controller, optional DSP or Mach3 control system

Optional components

1. Rotary axis: engraving cylindrical materials. 2. Servo motor and driver 3. 2.2kw/3.2kw water-cooled spindle, more power and strength.

Specifications:

No. | ITEM | DESCRIPTION |

1 | X,Y,Z Working Area | 600x900mm |

2 | Positioning Accuracy at Work | 0.03mm |

3 | Frame | Cast iron structure, aluminum gantry |

4 | Table Surface | Aluminum T-slot Table |

5 | X, Y,Z axis transmission | Ball Screw |

6 | Rail Configuration | Square rail |

7 | Spindle Power | Water-cooling 1.5KW |

8 | Spindle rotationg Speed | 0-24000RPM |

9 | Drive Motors | Stepper System |

10 | Working Voltage | AC220V/50HZ ; 60hz option |

11 | Operating System | Nc studio; DSP options |

12 | Command Language | G code, u00, mmg, PLT, HPG |

13 | Software Compatibility | Type3, Wentai (ArtCUT), ArtCAM, Aspire etc |

14 | Packing | Wooden case |

15 | Packing Size | 1520*1250*1750mm |

16 | Weight | 350kg |

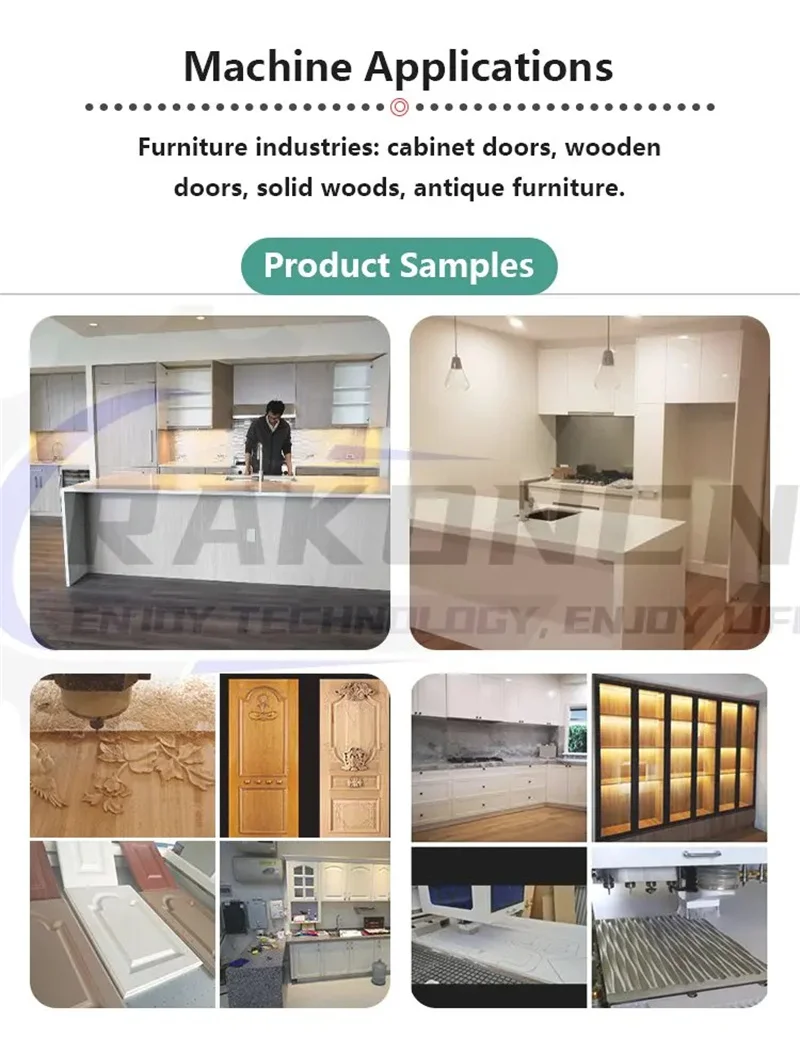

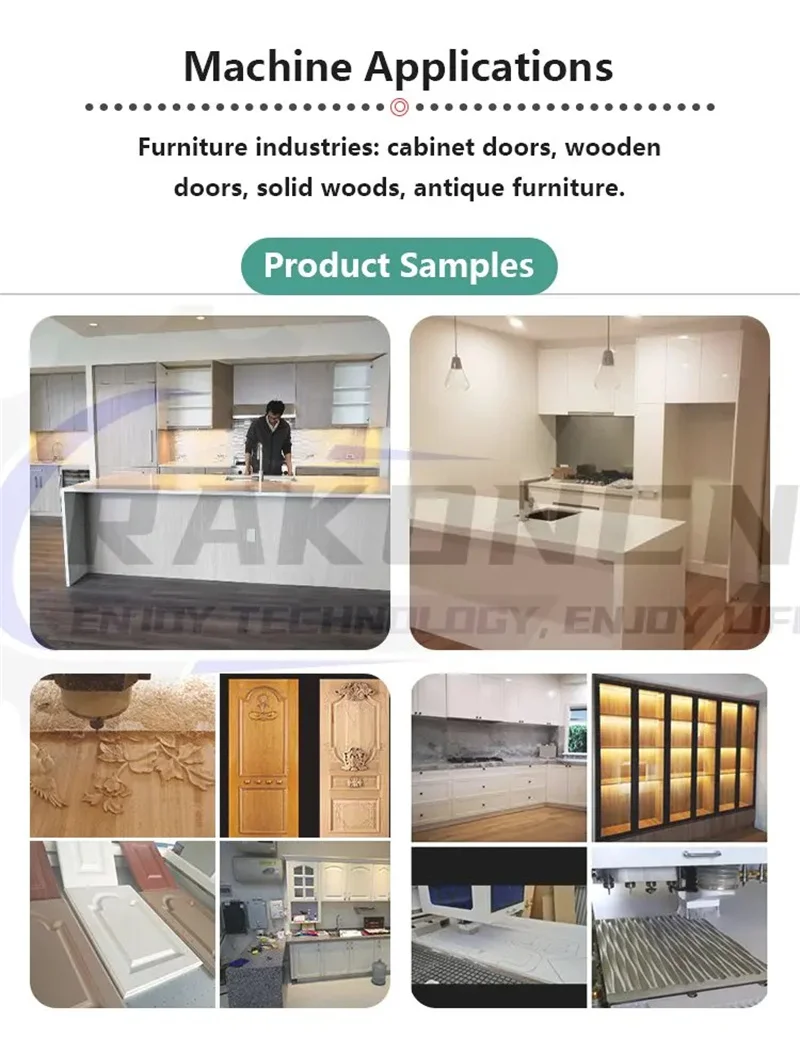

Applications:

1. Wood Furniture Industry: Wave Plate, fine pattern, antique furniture, wooden door, screen, craft sash, composite gates,cup board doors, interior doors, sofa legs, headboards ,game cabinets, computer tables, sewing machines table, instruments etc.

2.Advertising Industry: advertising identification, sigh making, Acrylic engraving and cutting, crystal word making,blaster molding,and other advertising materials derivatives making

3. Crafts: engraving characters of any language and patterns on gifts and souvenirs, primitive processing and shaping of artistic crafts, and stiletto

4. Moulding: engraving delicate letter and flower pattern, primitive and fine processing of the small mould.

5.Architectural models: engraving fine window, fencing and wall patterns, etc.

Application materials:

1.Wood: Plywood, Soft Wood, Hard Wood, MDF, Chipboard, etc.

2.Plastic: Acrylic, ABS, HDPE, PVC, UHMW, HDPE, etc.

3.Metal: Aluminium, Brass, Copper, etc,it needs extra cooling system .

4. Composite: Aluminium Composite, Copper Composite, Titanium, Composite, Zinc Composite, etc.

5. Plastics & Composites (ACP, ACM and solid surface material etc)